Products & Service

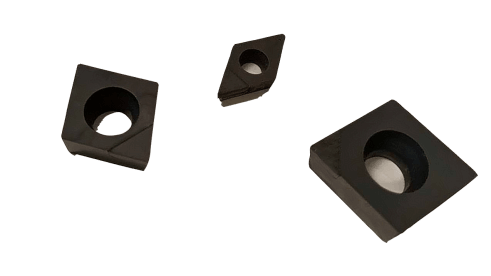

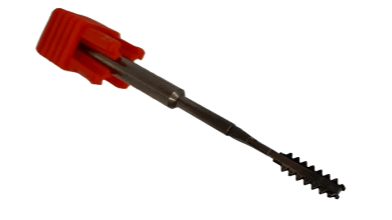

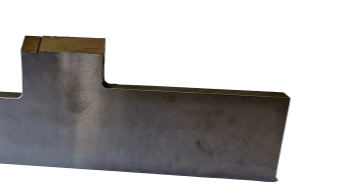

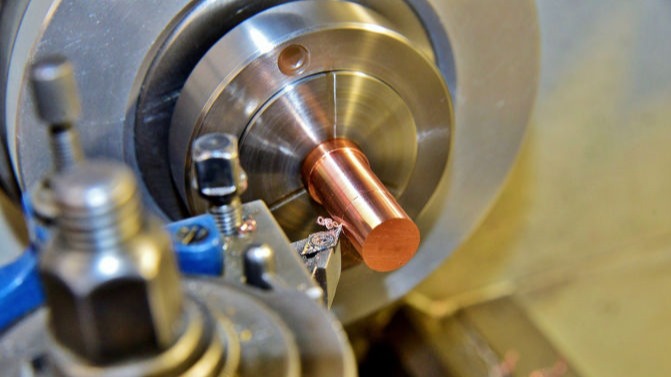

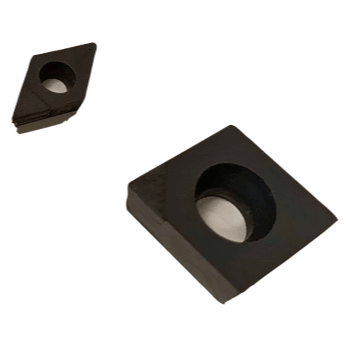

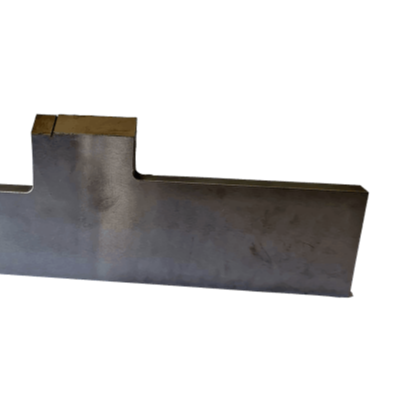

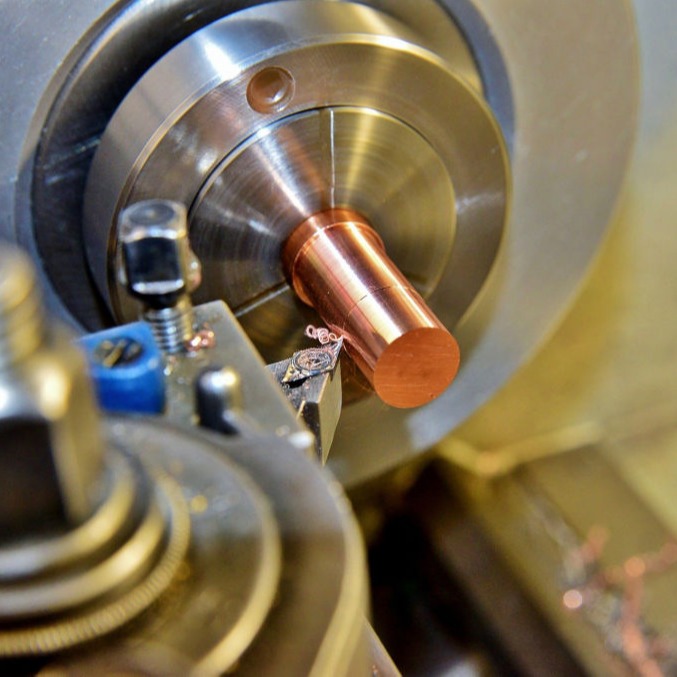

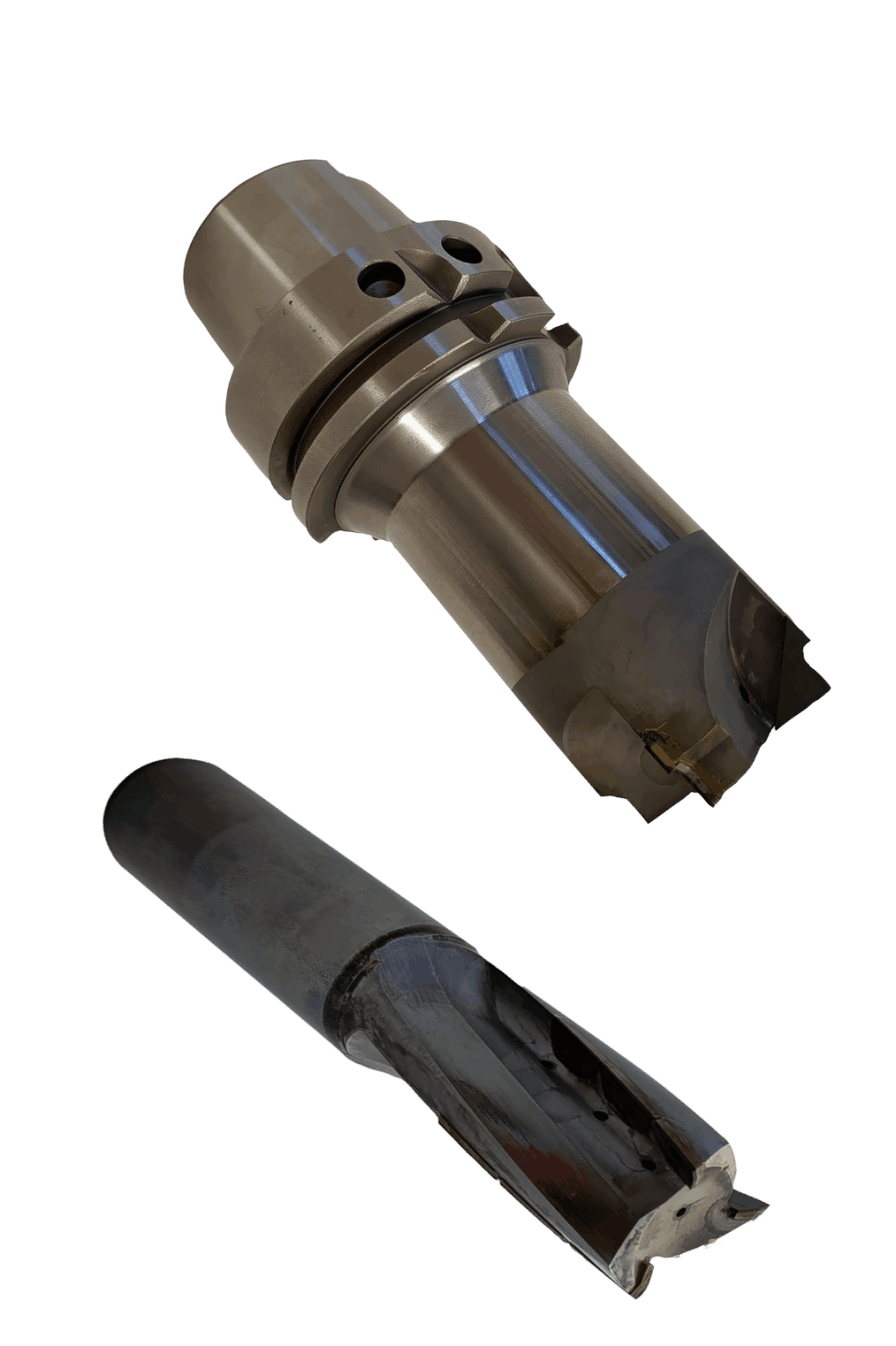

In addition to the production of customized PCD & CBN tools, we also offer custom-build post-processing or reconditioning of existing PCD & CBN tools.

Working with Sommerer GmbH & Co. KG tools offer a particular economic benefit with excellent, long-term cost savings: They have proven to have a long service life and they can be reprocessed several times by sharpening or refilling them with PCD / CBN.

We adjust and expand our portfolio continuously to offer the highest level of perfection and first-class service in its full scope.

Let our service impress you.

Feel free to contact us.